-40%

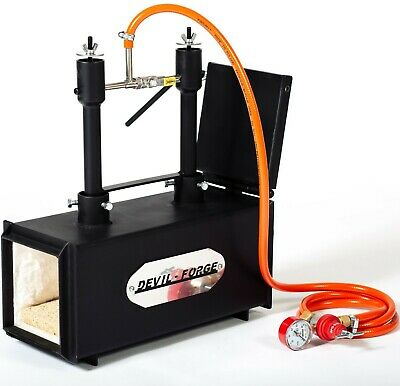

JF #1 Burner, blacksmith forge, raku kiln, foundry, assaying furnace, propane

$ 31.15

- Description

- Size Guide

Description

JF#1 BURNERItem #0001

Manufactured by Thermal Art Design

Made in Portland Oregon, USA

Features:

·

Long lasting stainless steel nozzle

TIG welded heavy duty construction

Up to 160,000 BTU out put

Precision machined and balanced for superior performance

Adjustable choke

Construction

These venturi style propane fired burners are naturally aspirated. The parts are formed using precision machined tool steel dies and assembled by a skilled certified TIG welder in precision alignment fixtures. Parts such as the 1/8 inch NPT nipple and the brass fuel orifice are machined on a precision turret lathe to ensure the highest quality in manufacturing.

Important things to observe are the finely tuned design of the stainless steel nozzle and the long life it will provide. Unlike some burners that are designed for similar applications which can only maintain ignition inside the chamber they were intended for (typically the refractory material of the device has a type of nozzle built in to it which wares out over time) these JF #1 burners maintain ignition as a standalone product. The nozzle will not ever reach critical melting temperatures as most homemade burners will. This means you can weld or assemble these burners by any type of fixture you require and be assured of a very long burner life. The burners come adjusted to burn neutrally in a wide variety of forge foundry and kiln constructions and can be choked to provide a perfect carburizing atmosphere for processes such as forge welding.

Why purchase a JF #1 burner?

If you are building your own forge, foundry, glass kiln, wax burn out kiln, or raku kiln often one of the most challenging, expensive and unforeseeable time consuming parts of the process is in obtaining or building a proper burner. These burners have thousands of hours of testing and use behind them. They perform excellently in multiple forge designs for blacksmithing. People have used them to fire foundries for melting aluminum and brass. They are being used to fire a wide variety of kilns and they have been adapted to a growing list of things.

These burners have been designed to operate efficiently with a hot neutral burning flame over a wide PSI range. While a person building a wax burn out kiln may only need to use 2 or 3 PSI a person with a forge or foundry may want to use 20 to 30 PSI. I recommend using at least a 30 PSI regulator with these burners so you can take advantage of the high out put potential and become familiar with the capabilities of the burner. (the regulators I carry are 30PSI) The BTU out put of these burners could be dramatically increased if the user chooses to adapt a regulator capable of putting out more that 30PSI but I personally have not done much testing with these higher pressures because most people find the heat out put is well with in their needs at 30 or less PSI. A common mistake people make is thinking they already have a suitable regulator that may have been taken off the "BBQ" which is a low pressure regulator and typically only capable of putting out 1 PSI. If you don't get a regulator from me make sure you understand that you will need to obtain a regulator of high enough pressure out put to operate the burner adequately for the heat requirements of your project.

Conclusion

If you are building some type of thermal equipment, these burners will bring you the highest level of satisfaction for an unbeatable price.

Assembly:

Products from Thermal Art design will possibly need light assembly before use so you should have basic hand tools and a knowledge of screwing together basic fittings. NPT threads will need to be sealed with pipe dope or Teflon tape. There is no need to seal flare fittings such as the swivel fitting on the regulator hose that connects to the M3/8 flare side of the valves I often carry because a flare fitting is self-sealing. I often ship my standard burner kits with the parts loosely assembled so the user can add in any additional plumbing they desire and do the final assembly themselves. Always remember to check plumbing parts valves and fittings for debris and make sure they are clean and clear before assembly. Use compressed air or wire brushes if necessary. I go to a lot of effort to ship clean ready to assemble parts by cleaning, blowing out with air, and using a variety of wire brushes but you should always do a final inspection before assembly.

Release of liability

Where ever flammable gases are used there are always potential dangers that must be foreseen and preparations must be made to avoid accidental fires and personal injury or even death. These products are designed to be used out doors or in a well ventilated shop area away from any other flammable materials. Thermal Art Design assumes no liability for any damages incurred to property or persons due to the use or possession of our products. Upon purchase owner agrees to assume all liability for accidents, damages, malfunction, misuse, or personal injury due to the use or possession of our products. Work safe.