-40%

Aquadry Heat Trailer-Phoenix- Drieaz- Delmhorst- Tramex- Dehumidifier- Air Mover

$ 5544

- Description

- Size Guide

Description

Multiple Units AvailableEverything

is included for full operation of this machine like hoses ext.

Xactware pricing.

WTR HEAT - base unit for 24 hours 200KBTU unit 0.00

WTR HEATX- Heat exchanger with air mover perday 5.00 (varies by location)

3 heat exchangers = 3 X 5.00 =5.00 MISC. Thermostatically controlledexhaust with ducting (equal to a dehumidifier) .00

WTR EQ Set-up, monitoring & take downper hour - Est. 2 hours .72

FEE PROP Propane charge .32 per gal. x 40gal. typical usage 2.80

TOTAL PER DAY CHARGE,830.52

How It Works

AquaDry Systems is a revolutionary portable hydronic system which uses focused high energy to efficiently dry out water damaged structures. It is safe, versatile, non-intrusive and environmentaly friendly. It is cost efficient saving both the operator and customer time and money.

The AquaDry System normally can dry a structure in two days or less. This is at least a 60% improvement in dry times compared with other systems/methods.

The following are typical examples of AquaDry System set ups:

•Drying out an entire structure

•Drying out a single room

•Drying out a crawl space or basement

The Facts

•Enclosed central heating systems (CSA certified)

•Time & cost savings on all jobs

•Dries effectively in all conditions

•Safe & Environmentally friendly (GreenSpec Listed)

•Hydronic system operation is safe and fuel efficient

•Can dry in all temperature ranges including frozen structures with no heat or electricity

•Simple on-board diagnostics

•Supervision is kept to a minimum with automatic system controls

•Use industry recognized pricing, no need to haggle (on Xactimate)

•Heating unit can be set up to 300 feet away from the target structure

•Easy to set up

•Large and small job capacity, from 500 to 90,000 + sq. ft. drying capability with a single machine – Larger spaces with multiple units

Simply Put...

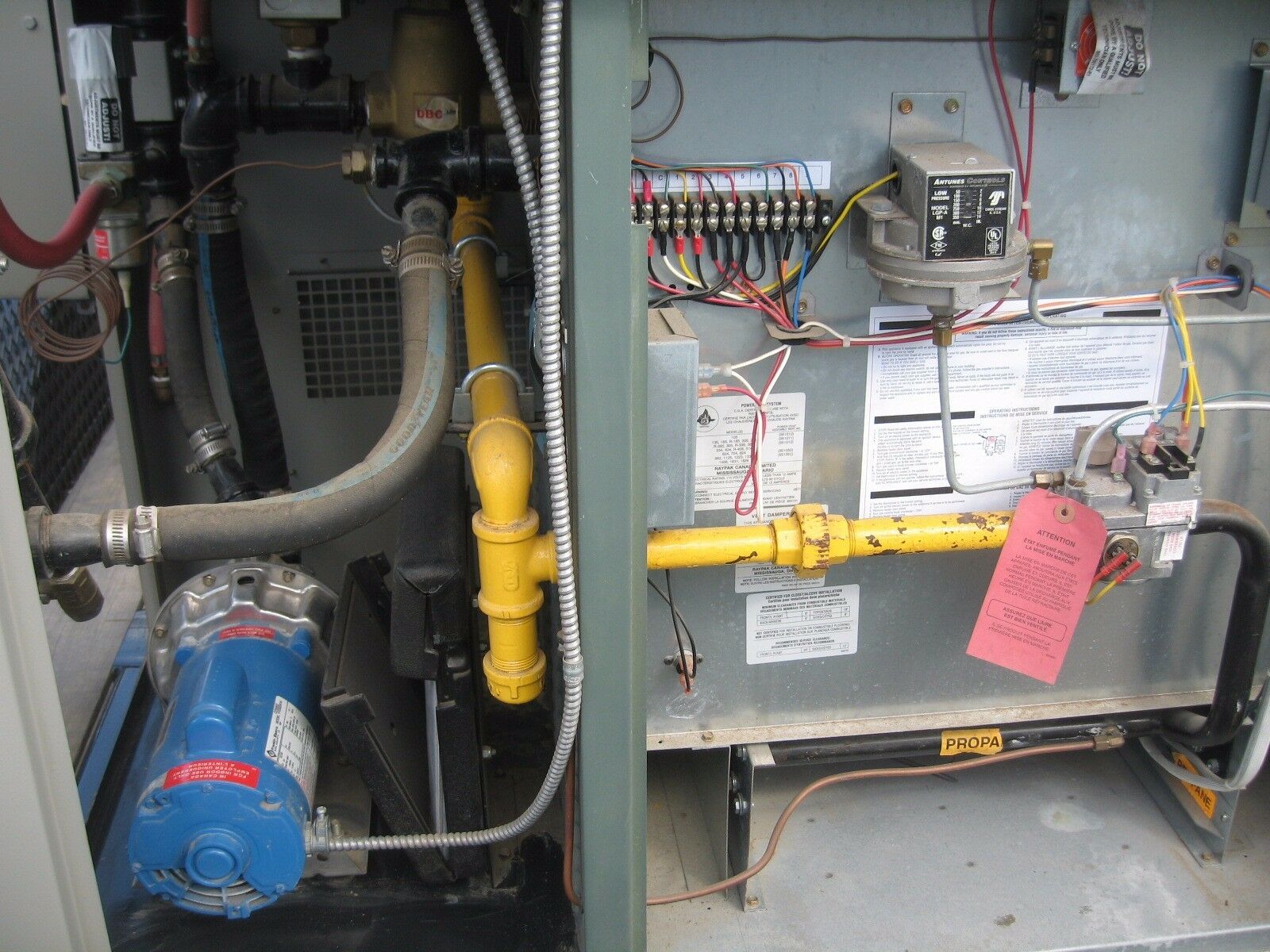

The AquaDry central heating module encloses an open-flame hydronic water heater which heats the transfer fluid. This heated fluid is then pumped through fluid circulation system loops to portable heat exchangers.

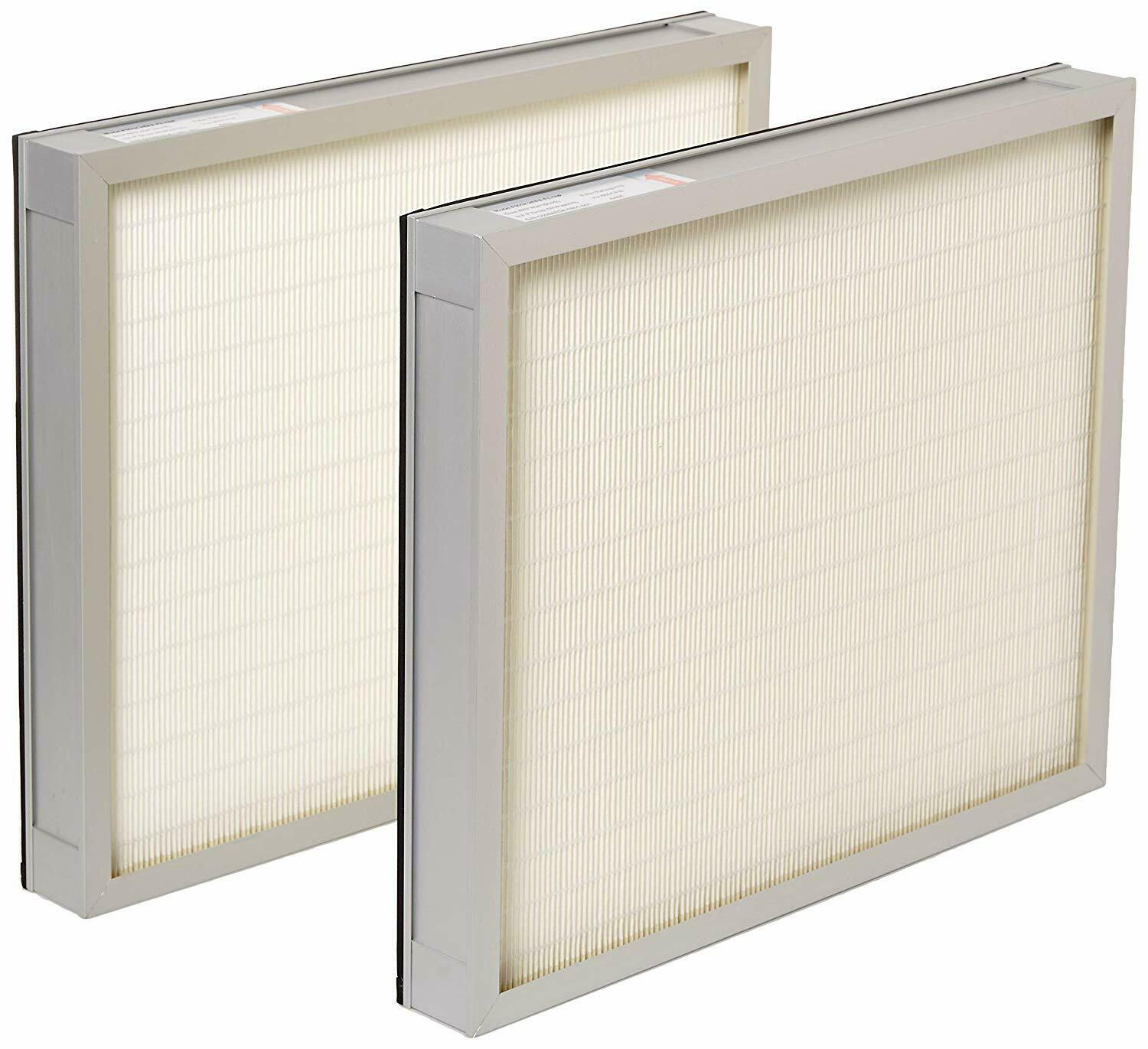

The portable heat exchangers deliver high CFM, hot, low RH (relative humidity) air into the wet environment. The hot air raises the dew point in the structure, allowing for rapid evaporation from the wet building materials. The exchangers are effectively positioned to provide pressurization on target wet zones directly.

Uniform air circulation created by air movers and well placed, multiple heat exchangers within the structure helps promote rapid and uniform moisture capture.

Postive structure pressure results in the saturated air being effectively exhausted out of the structure through selected ventilation points.

As long as the temperature within the space to be dried is higher than the ambient temperature, an accelerated rate of drying will be achieved. The flexiblity of the system configuration results in faster drying times with few "hot pockets".

The AQUADRY System is a revolutionary drying system, which can dry structures faster than conventional drying methods. The AQUADRY System introduces hot air with low humidity into the wet environment. The hot air raises the dew point in the structure, allowing for rapid evaporation from the wet building materials. The positive pressure along with air circulation created by air movers helps promote rapid evaporation and pushes the moist air out of the wet environment through a strategically placed egress point. This can be achieved as long as the temperature within the space to be dried is a least 10 to 15 degrees higher than the ambient temperature. The result is a dry environment achieved at a faster rate than conventional drying methods.

The AQUADRY System utilizes a hydronic water heater to warm a heat transfer fluid. The heated fluid is pumped through a fluid circulation system loop to portable heat exchangers placed at remote locations. The portable heat exchangers distribute the air in the dwelling allowing specific areas to receive optimum heat. The flexibility of the configuration of this system results in faster drying and fewer “hot pockets”.

Hydronic heat delivery Compact and portable trailer designs for easy positioning on the work site.All system operations are controlled and monitored from the central heating module control panel.

•Temperature control and fuel usage is automatic.

•Fluid circulation systems are low pressure and atmospherically vented.

•There is no chance of an explosion or line burst due to pressure build-up and no special boiler certification is required to operate the systems.

•Quick-connect hose couplers , “no-drain” fluid lines and a “rapid air elimination” feature ensures quicksetup-and-go operation.

Multi-light system operation feature for easy system troubleshooting

Features:

• Propane or natural gas fuel source.

• Compact and portable design for easy

positioning on the work site.

• All system operation is controlled and

monitored from the heat module control

panel

• Temperature control and fuel usage is

automatic.

• 8-light system operation feature for easy

system troubleshooting.

• Fluid circulation system is low

pressure and atmospherically

vented. There is no chance of

an explosion or line burst due

to pressure build-up. No

special boiler certification is

required to operate the

system.

• Quick-connect hose couplers,

“no-drain” fluid lines and a

“rapid air elimination” feature

ensures quick setup-and-go

operation.

Type......................................Electric spark ignition

Temperature Range..............120°F to 200°F (49°C to 93°C)

Fuel specs

Natural gas fired

*Input capacity ...............248,000 BTU/H

*Output capacity ............199,000 BTU/H

Gas pressure range.......5”-14” W.C.

Manifold gas pressure ...4” W.C.

Consumption - max. ......248 CU.FT/H (7 CU.M/H)

Propane fired

*Input capacity ...............248,000 BTU/H

*Output capacity ............199,000 BTU/H

Gas pressure .................11” W.C.

Manifold gas pressure ...10” to 11” W.C.

Consumption - max. ......2.71 US GAL/H (10.3 L/H)

Controls & monitoring...........Full gauge panel monitoring

circulation fluid temperatures &

pressures, fuel pressures

.......................................8-light system operation feature

for easy system troubleshooting.

Weight - basic.......................820 LBS. (372 KG)

Electrical ...............................115 V, single phase, 60 Hz, 15 A

Module fluid circulation system

Basic features....................Atmospherically vented low

pressure system, adjustable fluid

temperature control, auto

temperature bypass for heat

exchanger protection.

Heat transfer fluid (HTF)....Non-toxic propylene glycol / water

mixture, freeze protected

Lines & couplers................1” fluid circulation hose, 1“ quickcouplers

Circulation pump................3/4 HP, 30 GPM (136 LPM)

@ 30 P.S.I.

* No BTU deration for high altitude operation